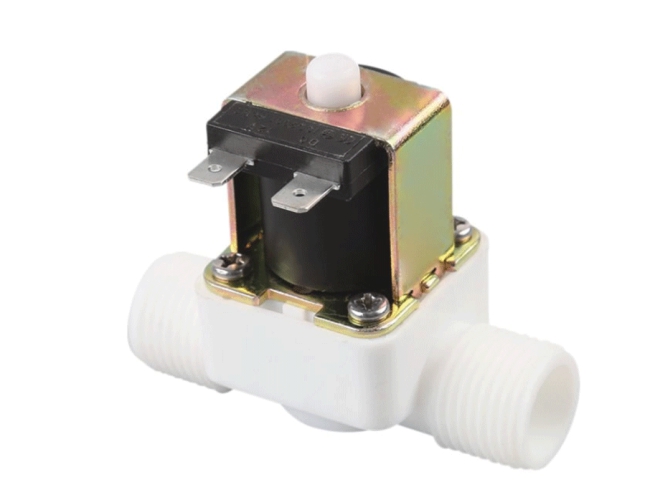

Accessory materials and specifications of the water inlet solenoid valve

1. The material of the valve body (also called the valve seat): generally divided into fully plastic valve bodies (that is, valve bodies that are all molded from plastic at one time, such as PP, PA material, etc.). This kind of valve is generally used for the kind of household appliances that have relatively low fluid temperature and relatively low fluid pressure); followed by the valve body that combines metal (copper or stainless steel) and plastic (usually the middle part is made of plastic, and the two ends of the interface are made of metal, using screws Connect them) This kind of valve is generally used for household appliances that are connected to high temperature and high heat, such as electric water boilers, solar water heaters, etc.); the other kind is an all-metal valve body (usually copper material), this kind of valve is more used For electrical appliances with a temperature higher than 100 degrees Celsius and high water pressure, such as a water discharge valve for small boilers, the disadvantage of this valve is that it is too expensive and is rarely used in general household appliances.

2. Inner core material: (The inner core here generally refers to rubber parts used for sealing water or blocking holes) One is rubber such as styrene-butadiene rubber, butadiene rubber, isoprene rubber, etc.; the other is silica gel ( Some household appliances must use silica gel inner core to reach the sanitary level, such as water dispensers, coffee machines, soymilk machines, etc.) It is a highly active adsorbent, an amorphous substance, and its chemical formula is mSiO2·nH2O. It is insoluble in water and any solvents, non-toxic, tasteless, chemically stable, and has high mechanical strength. It does not react with any substances except strong alkali and hydrofluoric acid.

3. Electromagnetic coil outer sealing material: (that is after the enameled wire is wound, it must be sealed with plastic and only two terminals are exposed) There are generally two outer sealing materials. One is (thermoplastic) flame-retardant polypropylene, that is, flame-retardant PP; The other is (thermosetting plastic) DMC bulk molding compound, product features:

(1) Excellent electrical insulation, arc resistance, and resistance to leakage traces.

(2) Excellent mechanical strength, flame resistance, and heat resistance.

(3) Excellent molding processability, low molding pressure, and short molding time.

(4) It can only be molded at one time. After reaching the molding temperature, it will cure and change chemically and have irreversible properties. This (thermosetting) DMC bulk molding compound is incomparable to flame-retardant PP. This is very important. If the water inlet solenoid valve has high safety performance and long service life, the solenoid coil sealed with this (thermosetting) DMC bulk molding compound will be better.

The above information is provided by plastic angle solenoid valve supplier.